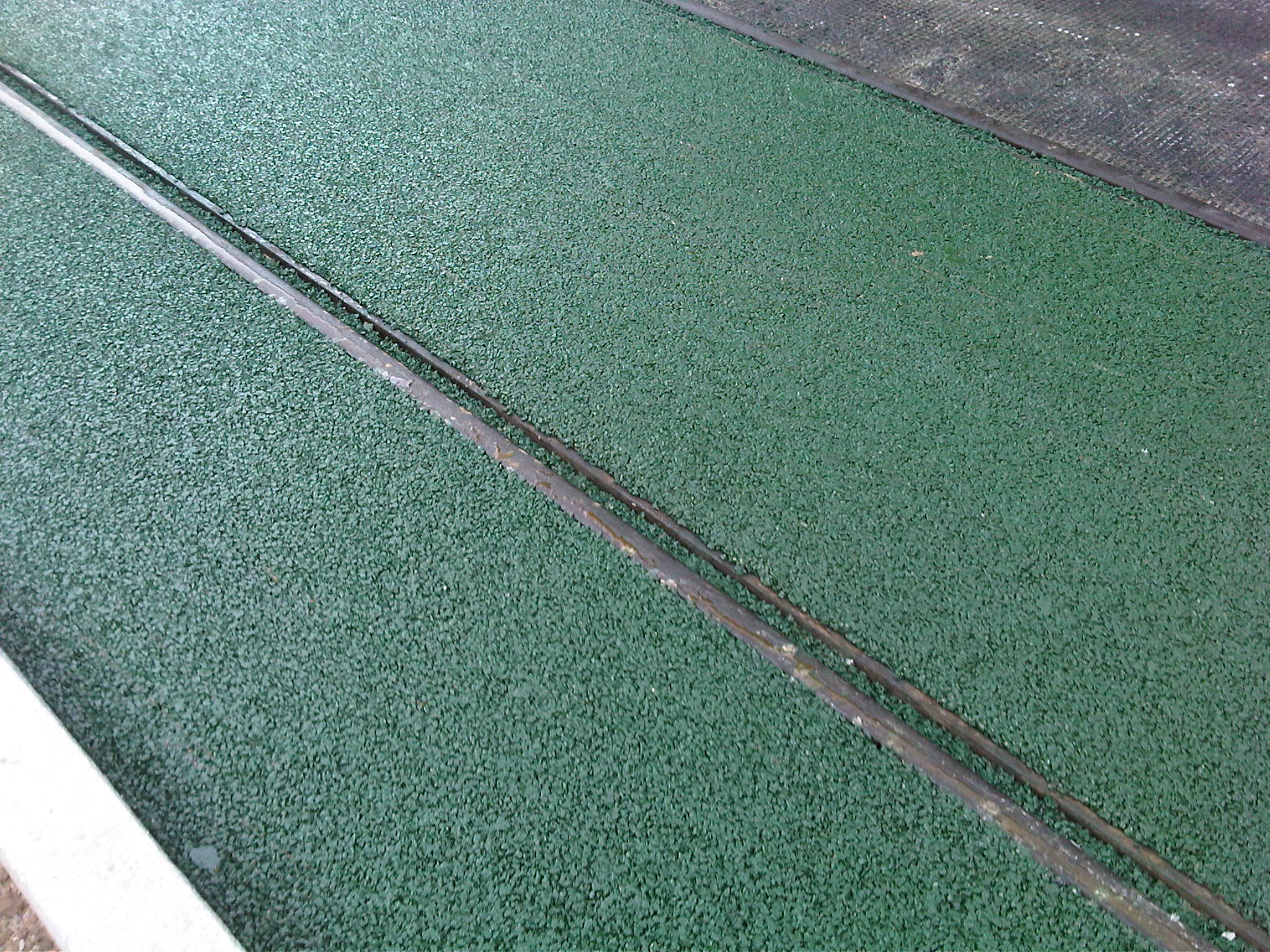

The synthetic binder BSC®, supplied in solid form, is used in the production of coloured hot mix asphalt. Using colour on pavements, cycle lanes, car parks, or city squares enhances the urban environment and improves road safety by highlighting danger zones.

Please fill in the contact form for MSDS request.

Additional Information

• Clear or coloured synthetic bitumen in solid form for use with hot mix asphalt.

• Coloured asphalt surfaces. • City squares, car parks, pavements, bicycle lanes, danger zone markings, crossroads, tunnels, school playgrounds, shopping centres, driveways.

● Long shelf life. ● Suitable for small, medium or large worksites. ● No specific equipment required (the coloured asphalt is manufactured in a traditional asphalt mixing plant). ● The bitumen is supplied in solid form for easy transportation, storage and handling. ● No colour loss as the binder is only heated when needed. ● Very good resistance to cracking. ● Good U.V. resistance. ● Resists any mechanical cleaning method. ● Excellent resistance to freeze/thaw cycles and to de-icing salt. ● Economical, no loss. ● No waste.

● Materials must first be heated between 180°C and 200°C. ● The 15 kg thermofusible bags containing the small BSC packs are introduced into the mixer of the asphalt plant. ● Mixing time must be at least 5 minutes to allow the packs to melt completely. ● When pigments are added to the clear bitumen, they must be injected after the BSC bags and another 30 seconds must be added to the mixing time. ● If the coloured asphalt is produced in a traditional black asphalt plant, check that the mixer and the aggregate storage bins are clean. If necessary, make two blind patches (heat aggregate without binder). ● The choice of aggregates is very important and plays a decisive role in determining the asphalt’s colour. We recommend using aggregates whose colour is as close as possible to the chosen coloured asphalt. ● If you plan to add fillers or fines, choose clear and limestone-type fillers. They must be inserted in the mixer last, once the asphalt has been produced, so as to avoid burning, which could give a darker tint to the asphalt’s colour. ● A clear emulsion primer is recommended prior to laying the BSC asphalt to ensure good adhesion. ● The timescale for opening to traffic is similar to that of traditional asphalt and varies according to the bitumen grade and the ambient temperature.

● Safety Blue, Copper Brown, Orange Brown, Clear, Boston Green, Safety Green, Safety Grey, Silver Grey, Ivory, Extra White Ivory, Oxide Red, Safety Red, Stone, Yellow, Ochre Yellow. ● Other colours available upon request.

● 500 g small bags packed in 15 kg thermofusible bags. ● 1,000 kg Big-Bag on pallet.

● Recommended dosage according to the grading curve: 5.2 % to 6 % of residual bitumen. ● Bitumen maturity: 24 hours. ● Equipment cleaning: use any petroleum-based solvent. Please download Technical Data Sheet for further information.

● Customs code 2715 000 00. ● Labelling: none.

● Must be stored in its sealed original packaging, between 5°C and 25°C. ● Shelf life : 3 years.